Short description

dinotec electrolysis systems for production of a highly effective disinfection solution from common salt, stable when stored. The basic version of the controller already includes redox and pH measurement as well as the corresponding dosing outputs.

Description

dinotec electrolysis systems for production of a highly effective disinfection solution from common salt, stable when stored. Integrated product tank to cover peak demand. The basic version of the controller already includes redox and pH measurement as well as the corresponding dosing outputs. The measurement technology can be easily extended to a complete measurement and control system for chlorine, redox and pH. Special characteristics Main system components are:

Technical data

System housing:

Plastic housing, protection class: IP 65

Supply voltage:

230V / 50Hz

Energy demand:

approx. 1.2kW/h

Display:

via large graphical display 100 x 30 mm

Operation:

Clear text menu with keys

Language:

Language selection

Production output:

approx. 200 g chlorine/h

Product concentration of:

approx. 6.4 g chlorine/l

Salt consumption:

approx. 790 g NaCl/h

Space requirements wall mounting plate:

1212 x 772 x 195 mm (hxwxd)

Transport weight:

approx. 59 kg

Operating weight:

approx. 63 kg

Flow control and monitoring

Yes

Monitoring of back pressure in hydrogen line

Yes

Softening plant:

integrated

Refill control in softener

Yes

Type of Operation:

stand-alone

Redox measuring amplifier

Measuring range:

-1500 mV to +1500 mV

Resolution:

1 mV

Ambient temperature influence:

50 ppm/K (12 mV)

Reference temperature:

23° C

Input resistance:

> 1012 ohm

Redox measurement:

via combination electrode without reference system

Calibration:

not required

pH measuring amplifier

Measuring range:

-1500 mV to +1500 mV

Resolution:

0.01 pH or 1 mV

Ambient temperature influence:

50 ppm/K (12 mV)

Reference temperature:

23° C

Input resistance:

1012 ohm

Calibration pH:

optional single-point or two-point calibration

Electrode check:

automatically after calibration

Temperature compensation of pH value:

automatic via PT1000 or manually adjustable

Temperature

Temperature input for measuring sensor:

PT1000

Measuring range:

-30°C to +140°C (+/-1%)

Inputs/outputs, control response

Type of control:

P, PI, or PID control optionally

Control:

optionally 1-position

Binary outputs:

2 potential-free output relays for disinfection, pH reduce/pH raise (pulse length, pulse frequency, On/Off), alarm

Maximum contact load (230V/AC):

370 W (inductive), 500 W (Ohm resistive load)

Max. switching current:

30V/10A, 115V/0,3A, 230V/0,12A

Digital inputs:

Empty signal chlorine, pH reduce, dosing stop

Environmental conditions

Working temperature:

5 to +50 C°

Storage temperature:

20 to 65 C°

Rel. humidity:

max. 90 % at 40 °C (non-condensing)

Application

Ecological and safety-conscious production of a disinfection solution containing chlorine for use in drinking water and process water disinfection, swimming pool water treatment to maintain the quality of hygiene parameters (TVO - German drinking water regulations, § 11 UBA - German Federal Environment Office). It must be ensured that only high-quality salt according to the manufacturer's specifications is provided as operating material for the Vodes BlueWave systems. Non-observance results in an exclusion of any statutory warranty/warranty claims. Manufacturer specifications for salt: NaCl min. 99.90 % / hardeners (sum Ca and Mg) max. 50 ppm / sulphate (SO4) < 400 ppm / bromide (Br) < 75 ppm / manganese (Mn) < 1 ppm / iron (Fe) < 2 ppm / components insoluble in water < 0.1 %. We recommend the use of dinosolit special salt tablets, otherwise it's the operator's responsibility to monitor the salt quality.

Safety information

No handling of or contact with hazardous materials required.

Disposal informations

There are no waste products that require a special form of disposal.

Storage instructions

Work environment for electronics

Storage temperature:

20 to 65 C°

Rel. humidity:

max. 90 % at 40 °C (non-condensing)

Supplementary information

Preliminary works by customer Installation of a backflow preventer, air inlet valve or pipe separator required, if demanded by the local utility companies. A separate technical room is not required.

Accessories

dinodos EASY, capacity 0.2 - 4.5 l/h

Peristaltic dosing pump in wall mounting case

Hose connection 6/4 mm

dinodos START

Peristaltic dosing pump in wall mounting case

with power cord l = 1.8 m grey, hose connector 6/4 mm

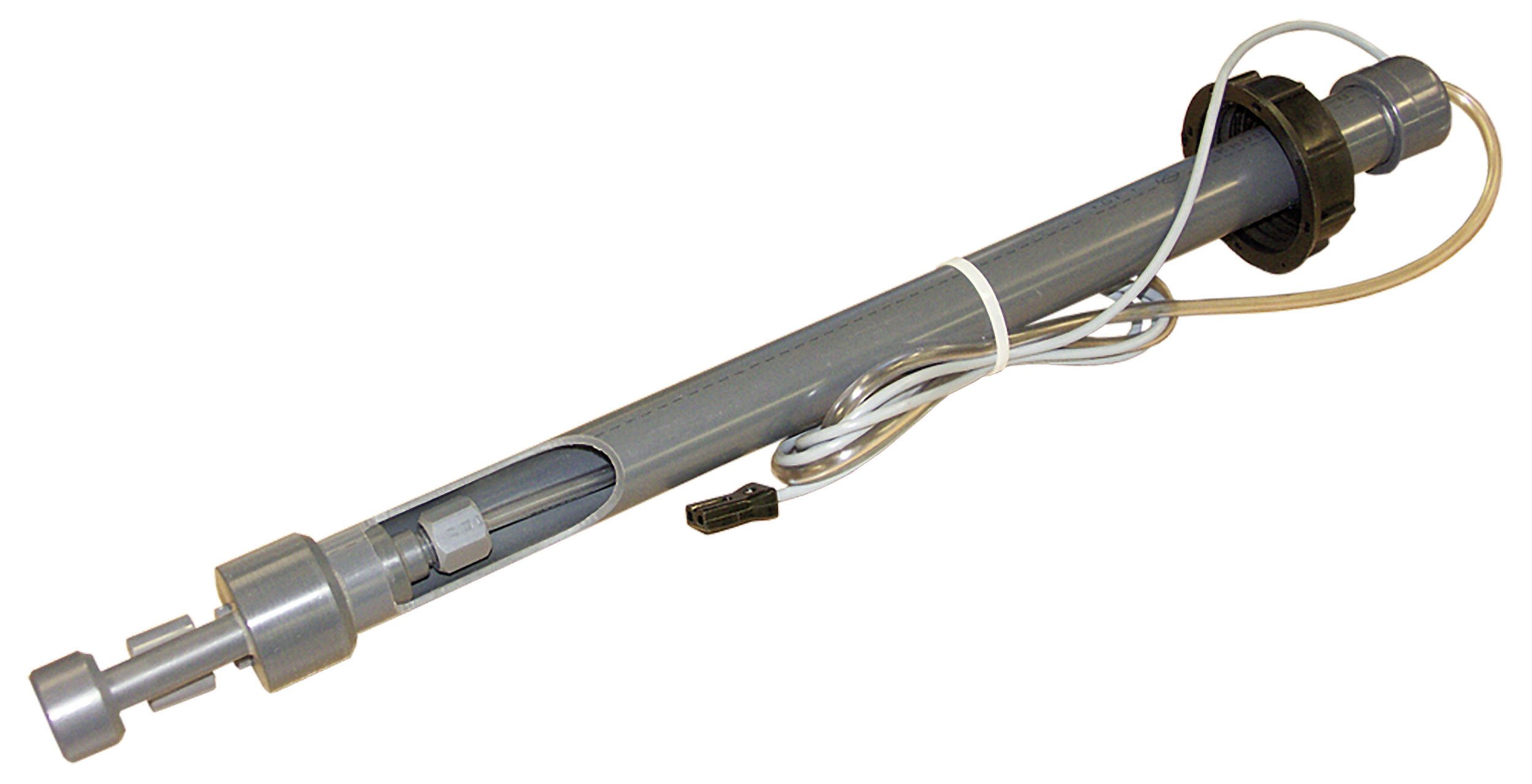

Dosing line, DN 4, 6/4 mm, PE, yellow

standard, for pH and flocculation, cut to 6m each

rolled and fixed with bands

Dosing line, DN4, 6/4mm, 6m piece

PTFE for extreme loads (10 bar up to 100°C)

rolled and fixed with bands

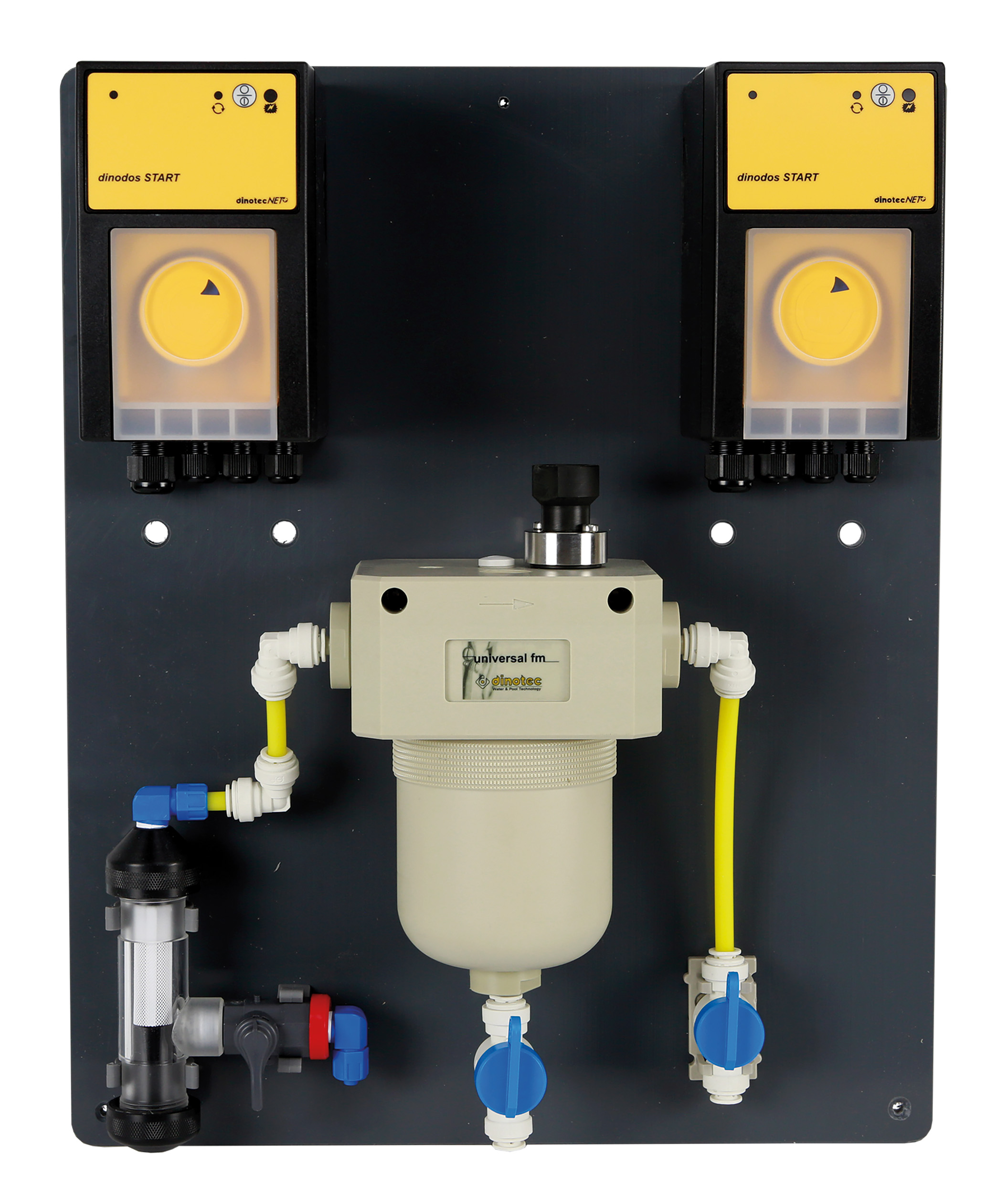

Extension set Cl, pH, Rx for VoDes BlueWave

with dinodos START, measuring board, measuring cell universal FM,

electrodes and accessories mounted on a plate

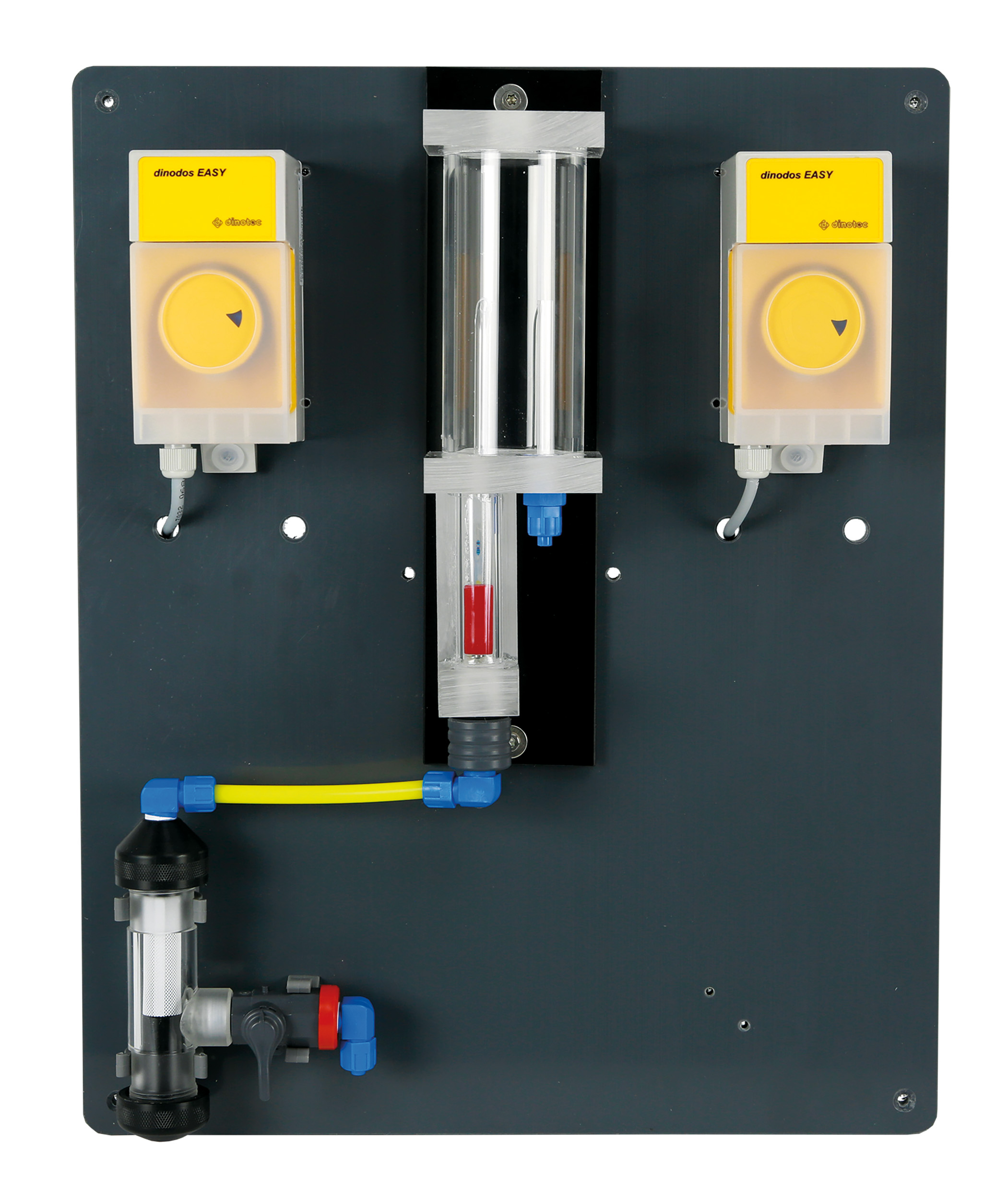

Extension set Rx, pH for VoDes BlueWave

with dosing technology dinodos EASY, flow cell,

electrodes and accessories mounted on a plate

Measurement technology CL, pH, Rx with measuring board

Measuring cell universal fm up to 10 bar, electrodes

and accessories mounted on a plate - for process water

Measurement technology CL, pH with measuring board

Measuring cell universal fm up to 10 bar, electrodes

and accessories mounted on a plate - for process water

Deutsch (DE)

Deutsch (DE)  English (UK)

English (UK)